Introduction

As a radio network operator, you know that radio networks are at the heart of an ever expanding number of service provision organizations. Emergency service, public safety and commercial users rely heavily on radio communications technology and are increasingly demanding higher levels of network performance.

As a result, network operators are facing demanding KPIs with non-performance penalties. To verify and demonstrate compliance, Periodic Maintenance Inspections (PMI) are performed to audit system performance. Unfortunately, the staff required to undertake this work puts maintenance and operating budgets under pressure – and the network down-time to do the PMI measurements may also be counted against the total network availability metrics.

The Problem

So how do you meet your budget and minimise downtime and outages without increasing costs or staff numbers? The obvious answer is real-time, continuous system performance monitoring. And where better to monitor performance than right at the antenna? It’s the transmitter power leaving, and the receiver signals being received by, the site’s antenna(s) that’s important. If the system’s signals aren’t sent and received efficiently by the site’s antenna(s) without degradation or interference, the network can’t deliver its service to the users.

But as you know, monitoring performance at the antenna on an operational system is not easy. By the time you get to the antenna feeder cable, all the transmitters have been combined. It is no longer possible to raise an alarm based on a simple power level measurement. To detect a transmission fault you really need a spectrum analyzer. Measuring antenna VSWR at this point while the system is operating is also difficult. Using a communications site analyser is not necessarily the answer as most test equipment types expect to work with a single carrier and cannot measure multiple simultaneous carriers accurately.

In any case, such test equipment is expensive and it would be hard to justify having one or more spectrum or communications site analysers permanently installed at each site.

The Solution

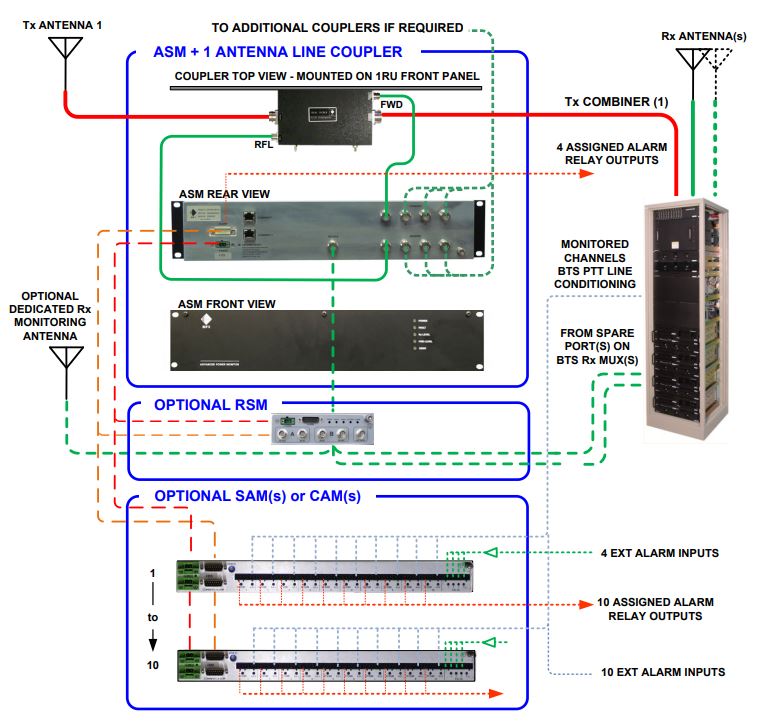

The RFI Antenna System Monitor (ASM) is the cost-effective solution to the real-time system performance monitoring challenge. The ASM can make channelized (i.e. per-carrier) Tx power and VSWR, Rx received signal level, and Tx-Rx intra-system isolation and carrier rejection measurements at the antenna feeder(s) on a continuous 24×7 basis – and can generate alarms based on user-configurable thresholds. Integrating the ASM into your system is very easy, with its Ethernet ports providing access for its userfriendly internal webserver GUI for configuration and status display, and SNMP, SMTP (Email) and dry contact relays for alarm reporting.

Multiple Tx combiner systems on the site can also be monitored by one ASM and optional Receive Systems Modules (RSMs) and Site Alarm Modules (SAMs) can be added to further enhance the ASM’s capabilities to include Receiver Diversity and Dual Receiver Systems compatibility, temperature and analogue voltage and digital inputs monitoring, and an increased number of alarm output relays. Various third-party monitoring software packages available in the marketplace also support the ASM, integrating the ASM’s measurement and alarm data into their overall equipment monitoring and alarm notification and data analytics capabilities.

The Numbers

Let’s do some math. If there were 20 sites in your system and you needed to do a PMI on each of these sites to check the Tx power, VSWR, Rx performance on each channel and the health of the site’s antenna(s), twice a year…. and let’s also assume each sites requires a 5 hour outage to do the PMI and that you need two technicians on site for that period. In addition, there’s travel time …. say 2 hours out, 2 hours back on average.

Finally, there’s the burden at the Network Operations Centre (NOC) to manage both the site unavailability over that period and the PMI process (say another technician for the same 5 hour period).

All that adds up to 23 man-hours expended per site visit. So the total effort for 20 sites, twice a year, is 920 man-hours or 115 mandays per year, plus the unavailability element – and this is still not real time monitoring.

Even if we cost the technicians at only $70 per hour, the total comes to 920 x $70 = $64,400 or $3,200 per site, per year. These figures assume all sites are within about 90km (55miles) or 2 hours’ drive of the service centre. Put a few sites in more remote country areas and the costs can escalate very quickly.

Compare this with an approximate $5,000 once-off capital cost per site to provide 24×7 real-time monitoring for up to four antennas, and with a level of granularity you can’t hope to replicate with PMIs.

Other Benefits

The benefits don’t stop with the cost savings. Knowing the health of an antenna prior to the site visit may mean that a spare antenna and rigging crew aren’t required. The ASM can store historical Tx power and VSWR, Rx received levels and Tx-Rx intra-system isolation and carrier rejection measurements for later off-line analysis too. This gives you data to monitor performance trends and intuitively identify the need to perform network maintenance even before coverage-impacting degradation occurs. This historical data is presented in CSV file format, allowing processing and presentation to be performed or automated easily in Microsoft® Excel etc.

If, for example, the antenna or feeder suffers damage from birds, hail or snow, it’s likely this will show up as degrading VSWR before the users notice any reduction in network coverage performance. That gives you, the network operator, the ability to conveniently schedule a site maintenance visit, possibly avoiding the need to send a technician to site urgently or after hours (which are usually at higher labour rates).

The ASM monitors system performance in a permanently installed, non-intrusive way. Repeatedly disconnecting and reconnecting RF connectors to perform PMIs compromises their performance. Insertion loss, VSWR and especially PIM (Passive Intermodulation) performance – so critical in today’s digital networks – can be degraded. With an ASM installed, there are fewer disconnection cycles on these critical connectors, resulting in higher system integrity and improved long-term performance and reliability.

Finally, the ASM brings an enhanced level of remote monitoring capability to each of your sites – particularly if other equipment at the site is also being monitored by ASMs enhanced with RSMs and SAMs. Equipment can also be controlled remotely – such as starting generators, turning on night lighting, etc.

Most importantly, PMIs, with their associated down-time, become largely unnecessary due to the 24×7 monitoring by the ASM. You are able to see exactly what each of your transmitters is doing right at the antenna feed. With this 24×7 monitoring, and the benefits of improvements in maintenance practices, your Grade of Service, response times and Mean-Time-To-Repair (MTTR) will all improve. For mission-critical networks, system availability is maximized and down-time is reduced.

In Summary

None of this was really an issue before PMIs became a genuine expectation. Now that PMIs are very much a requirement for any significant network, the installation of an ASM brings Operations, Maintenance and Opex improvements – all with a short payback period.

While the ASM offers truly unique measurement and alarm reporting functionality, its real value lies in its ability to increase network availability, reduce maintenance costs, and to free-up highly valued and increasingly expensive and hard to find labor resources.